Qingdao Kunyuan Machinery Co.,Ltd.

Address: Mingguan Road No.729 Huangdao area Qingdao china

Phone:

13506429902

13963992990

Tel: 0532-86151277

Fax: 0532-89050585 86152277

Technical Advisory: 13506429902

E-mail: [email protected]

[email protected]

PRODUCT CLASS

Aluminum profile through shot blast..Marble Shot Blasting MachineH Type Section Steel Shot Blasting ..Gear Shot Blasting MachineIn Addition To Dust EquipmentsSteel Pipe Inner Wall Shot Blasting..Steel Pipe Outer Wall Shot Blasting..Big Steel Structure Shot Blasting M..Spring Shot Blasting MachineHoist Hook Shot Blasting MachineSteel Pretreatment Complete lineSteel Belt Shot Blasting MachineRebar Shot Blasting MachineSprayed The Pill MachineRoller Shot Blasting MachineRolling Drum Shot Blast Cleaning Ma..Vertical Steel Plate Shot Blasting ..Portable Shot Blasting MachineApron Tumblast Shot Blasting Machin..Anchor Chain Shot Blasting MachineWear-resistant Sparc-partsThe Blast WheelSpraying Sand RoomGas Cylinder Inner Wall Shot Sprayi..Gas Cylinder Outer Wall Shot Blasti..Tnclined Rolling Drum Shot Blasting..Bent Axle Shot Blasting MachineResin Sand EquipmentsCar Shot Blasting MachineNet Belt Shot Blasting MachineRubber Apron Tumblast Shot Blasting..Small Steel Pipe Inner Wall Shot Sp..Small Steel Pipe Outer Wall Shot Bl..The Tach Derrick Chain Cleaning Sho..Sand Processing EquipmentsHook-turntable Shot Blasting Machin..Trolley Shot Blasting MachineSucker Rod Shot Blasting MachineRotary table blasting machineSteel plate profile surface cleanin..

CONTACT US

Company Address: No.427 lingqueshan road huangdao area Qingdao

Postal Code: 266400

Phone: 13506429902

13963992990

Tel: 0532-86151277

Fax: 0532-86152277

Technical Advisory: 13506429902

E-mail: [email protected]

News

Application of Magnetic Air Separator in Shot Blasting Machine

The separation effect of the shot, sand and ash separator in the shot recovery system directly affects the life of the wear parts and the chamber  body guard of the shot blasting machine. The commonly used separator adopts wind separation to separate the projectiles, sand and dust in the recovered shot. It is easy to cause incomplete separation during the use process. The recycled projectiles contain impurities such as dust and sand, and the projectiles entering the shot blasting machine contain impurities. The more impurities, the more serious the wear on the wearing parts of the shot blasting machine, such as the guard plate, the blade, the shot separation wheel, and the directional sleeve, which reduces the service life of the wearing parts and increases the production cost. The magnetic air separator separates the sand, dust and projectiles in the pellets by means of magnetic separation + air separation, which improves the separation effect.

body guard of the shot blasting machine. The commonly used separator adopts wind separation to separate the projectiles, sand and dust in the recovered shot. It is easy to cause incomplete separation during the use process. The recycled projectiles contain impurities such as dust and sand, and the projectiles entering the shot blasting machine contain impurities. The more impurities, the more serious the wear on the wearing parts of the shot blasting machine, such as the guard plate, the blade, the shot separation wheel, and the directional sleeve, which reduces the service life of the wearing parts and increases the production cost. The magnetic air separator separates the sand, dust and projectiles in the pellets by means of magnetic separation + air separation, which improves the separation effect.

body guard of the shot blasting machine. The commonly used separator adopts wind separation to separate the projectiles, sand and dust in the recovered shot. It is easy to cause incomplete separation during the use process. The recycled projectiles contain impurities such as dust and sand, and the projectiles entering the shot blasting machine contain impurities. The more impurities, the more serious the wear on the wearing parts of the shot blasting machine, such as the guard plate, the blade, the shot separation wheel, and the directional sleeve, which reduces the service life of the wearing parts and increases the production cost. The magnetic air separator separates the sand, dust and projectiles in the pellets by means of magnetic separation + air separation, which improves the separation effect.

body guard of the shot blasting machine. The commonly used separator adopts wind separation to separate the projectiles, sand and dust in the recovered shot. It is easy to cause incomplete separation during the use process. The recycled projectiles contain impurities such as dust and sand, and the projectiles entering the shot blasting machine contain impurities. The more impurities, the more serious the wear on the wearing parts of the shot blasting machine, such as the guard plate, the blade, the shot separation wheel, and the directional sleeve, which reduces the service life of the wearing parts and increases the production cost. The magnetic air separator separates the sand, dust and projectiles in the pellets by means of magnetic separation + air separation, which improves the separation effect.

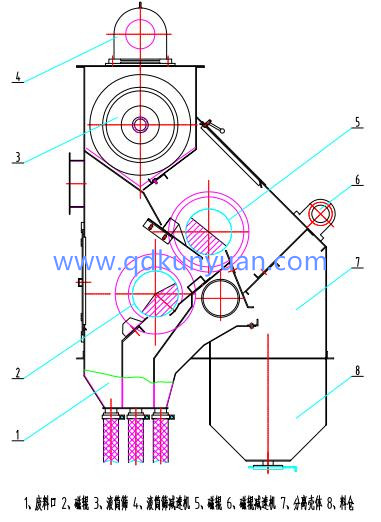

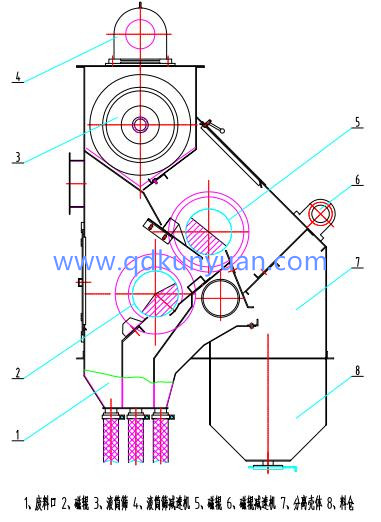

Structural features of the magnetic wind separator: see figure

The sand, dust and projectile mixture after shot blasting are transported to the screw of the magnetic air separator through the bucket elevator. The screw rotation pushes the shot mixture to the trommel screen, and the large particles of impurities are screened by the trommel screen and sent to the waste box and passed The waste pipe is sent out. The dust and projectiles are uniformly clothed by the outer spiral of the trommel screen to form a curtain. The primary air selection sucks the dust away. The primary magnetic roller rotates to separate most of the projectiles and enters the silo after the secondary air selection. After the magnetic separation, it is returned to the chamber through the flow pipe and reused for the second time.